IVD Device Development

Product development is hard. It is a journey down a previously unexplored path with twists and turns and unexpected failures. It is even more difficult when it involves the integration of new technology and the uncertainty of how a system should perform. These challenges fall heavily on the growing number of engineers designing microfluidic devices to meet the demands of the IVD market.

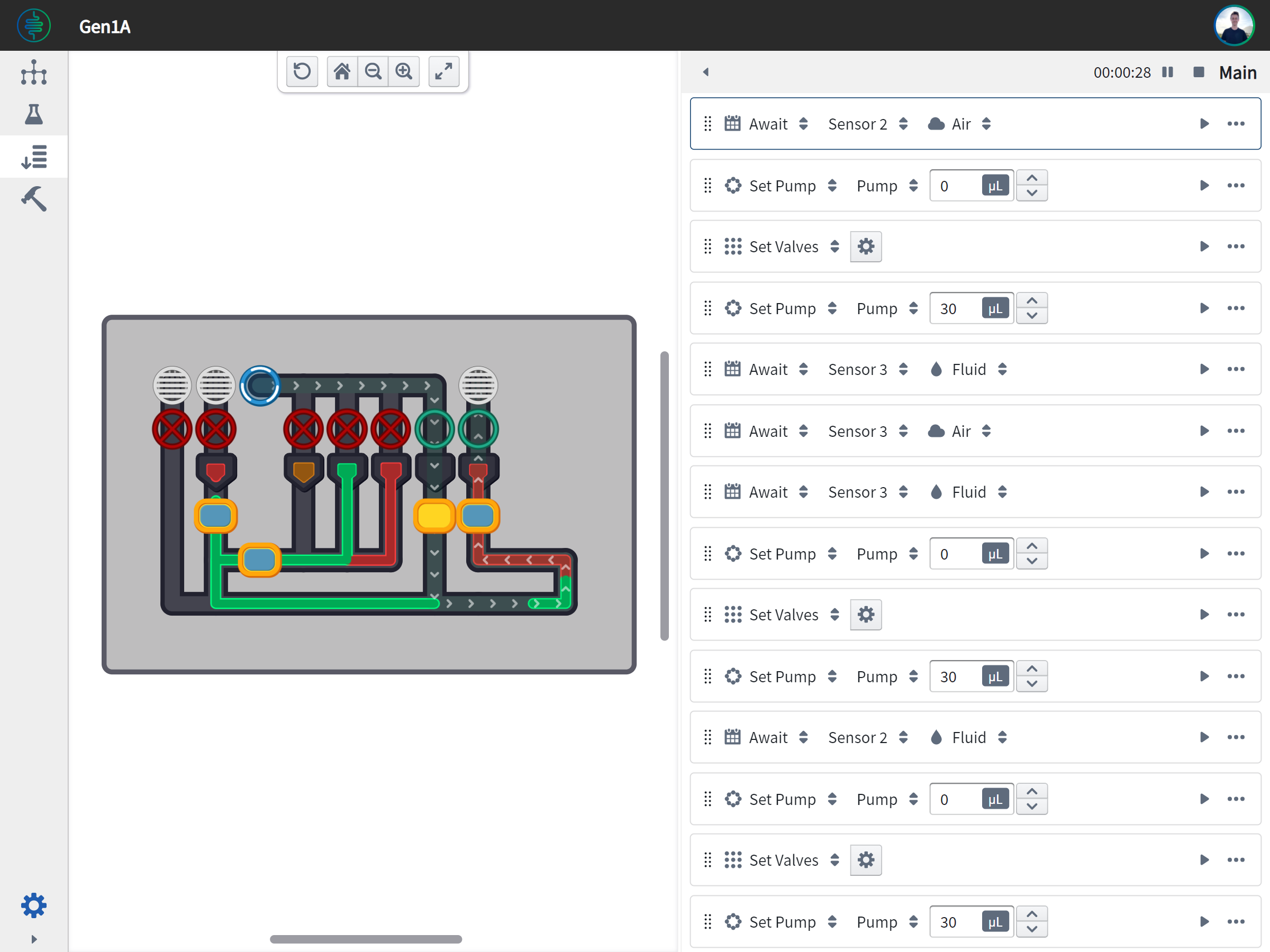

Engineers must understand the underlying assay and its protocol to design a device that can reproduce the steps efficiently and effectively. The process of translating this procedure into a finished design however can be extremely complicated. IVD devices may include several fluidic steps to achieve even basic functionality. The designer is not able to visualize every state in a single design or picture. At any given glance it is difficult to determine where fluid volumes are, where they came from, and what they are mixed with. It is also highly probable that the underlying assay requirements could change throughout the development cycle. The IVD designer must be prepared to change the design without starting from scratch.

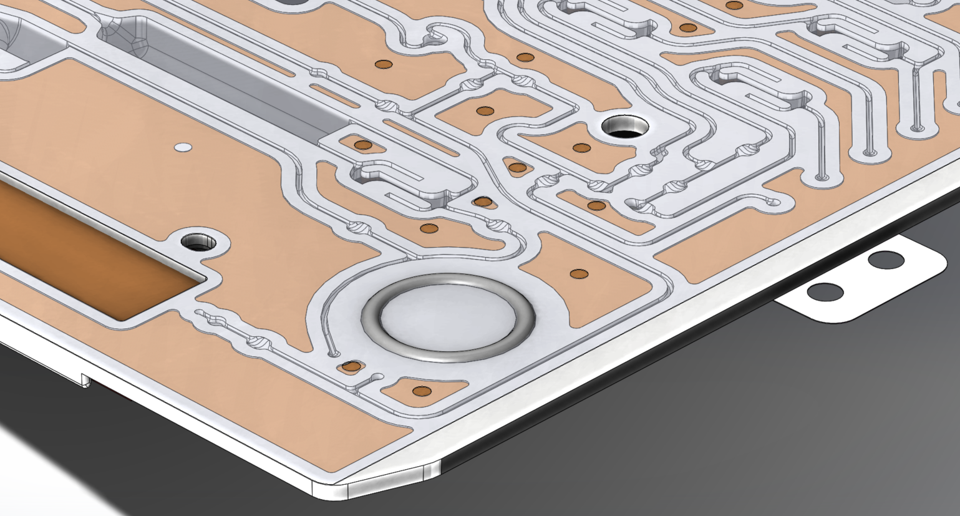

Engineers also face a challenge in testing their designs before building a production-ready assembly. Design teams cannot afford to forget about an air segment or contaminating fluid left behind, and frequent testing ensures that the design performs as intended. Because mechanical surface properties heavily influence the performance of microfluidic devices, it is not often feasible to use rapid prototyping technology to build and test product design iterations. Teams often compromise with long lead times and expensive injection mold changes to validate their designs. Flow Circuits seeks to help these teams by empowering them to iterate designs quickly and simulate their performance before the first mold is made.

Flow Circuits is a modern web-based alternative to using expensive and cumbersome CAD programs. It enables engineers to design fluidic circuits with channels, pumps, valves, chambers, sensors, and vents, write scripts to create an automated step-by-step protocol, and test that design with circuit simulation. The script logic can be exported to control instruments with software provided by Flow Circuits Engineering Services.

If you’ve never tried Flow Circuits, create an account today. See for yourself just how fun and delightful using it can be. It will change the way you work by speeding up your workflow, reducing the number of iterations, and providing you with the confidence that your circuit is designed correctly, *the first time*.